ALTAIR 70 P

Semiautomatic bundling machine with pusher - Sealing Bar 700 mm

Minipack®-Torre proposes a range of semi-automatic and automatic bundling machines characterized by the great compactness, high performances and excellent safety standards, guaranteed by a photocell that locks the activity of the welding bar in the presence of obstacles.

Semiautomatic bundling machine with pusher - Sealing Bar 700 mm

Semiautomatic bundling machine with pusher - Sealing Bar 700 mm - PLC 4

Semiautomatic bundling machine with pusher - Sealing bar 900 mm

Semiautomatic bundling machine with line infeed - Incorporated tunnel - Sealing bar 500 mm

Semiautomatic bundle packing machine with line infeed - Incorporated tunnel - Sealing bar 700 mm

Semiautomatic bundle packing machine with double motorised belt - Incorporated tunnel - Sealing bar 700 mm

Semiautomatic bundle packing machine with double motorised belt - Incorporated tunnel - Sealing bar 900 mm

Semiautomatic bundle packing machine with double motorised belt - Incorporated tunnel - Sealing bar 1150 mm

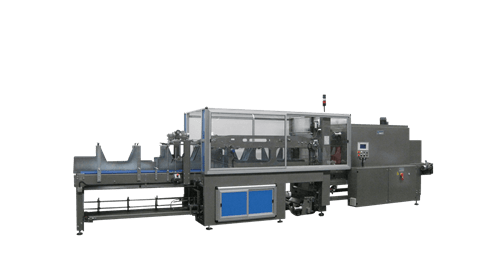

Automatic bundle wrapping machine with 1 track loading belt at 90° and pneumatic pusher - With 500 mm sealing bar

Automatic bundle wrapping machine with 1 track loading belt at 90° and pneumatic pusher - With 700 mm sealing bar

Automatic bundle wrapping machine with 1 track loading belt at 90° and pneumatic pusher - With 900 mm sealing bar

Automatic bundle wrapping machine with Schneider plc, 1 track loading belt at 90° and pneumatic pusher - With 500 mm sealing bar

Automatic bundling machine with 1 track loading belt at 90° and electric pusher - With 700 mm sealing bar

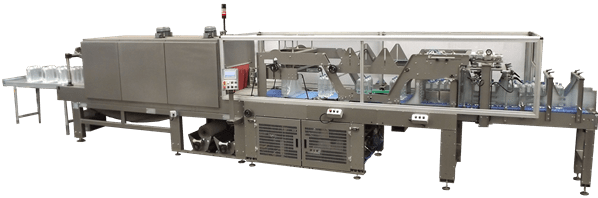

Automatic bundling machine with PLC, loading and unloading belt - With 700 mm sealing bar

Automatic bundling machine with PLC, loading and unloading belt - With 900 mm sealing bar

Automatic bundling machine with PLC, loading and unloading belt - With 1150 mm sealing bar

Automatic bundle packing machine with PLC and 3 inverters for the belts, loading and unloading belt

Automatic bundle packing machine with PLC and 3 inverters for the belts, loading and unloading belt

Automatic bundle packing machine with PLC, 1 track loading belt at 90°, pneumatic pusher and unload belt

Automatic bundle packing machine with PLC, 2 track loading belt at 90°, pneumatic pusher and unload belt

Automatic bundle wrapping machine with PLC, 1 track loading belt at 90°, automatic loading of cardboard flaps, pneumatic pusher and unload belt

Automatic bundle wrapping machine with PLC, 2 track loading belt at 90°, automatic loading of cardboard flaps, pneumatic pusher and unload belt

Automatic bundle wrapping machine with plc, 1 track feed belt arranged at 90°, pneumatic pusher and chain conveyor to space out the packages

Automatic sealing bar bundle wrapping machine with plc and multiline divider (6 tracks)

Automatic sealing bar bundle packing machine with plc, multiline divider and automatic loading of cardboard flaps

Automatic sealing bar bundle packing machine with plc, multiline divider (6 tracks), automatic loading of cardboard trays or flaps, tray former

Automatic sealing bar bundle packing machine with plc, multiline divider (6 tracks), automatic loading of cardboard trays or flaps, tray former

Automatic seamless film bundle packing machine with plc and multiline divider (6 tracks)

Automatic seamless film bundling machine with plc and multiline divider (6 tracks)

Automatic film seamless bundling machine with plc and multiline divider (6 tracks) and automatic loading of cardboard flaps

Automatic film seamless bundling machine with plc and multiline divider (6 tracks) and automatic loading of cardboard flaps

Automatic seamless film bundling machine with plc and multiline divider (6 tracks) and automatic loading of cardboard trays or flaps, tray former

Automatic seamless film bundling machine with plc and multiline divider (6 tracks) and automatic loading of cardboard trays or tray former

Automatic seamless film bundling machine with plc and multiline divider (6 tracks) and automatic loading of cardboard trays or flaps, tray former - also for film only

Automatic seamless film bundling machine with plc and multiline divider (6 tracks) and automatic loading of cardboard trays or flaps, tray former - also for film only

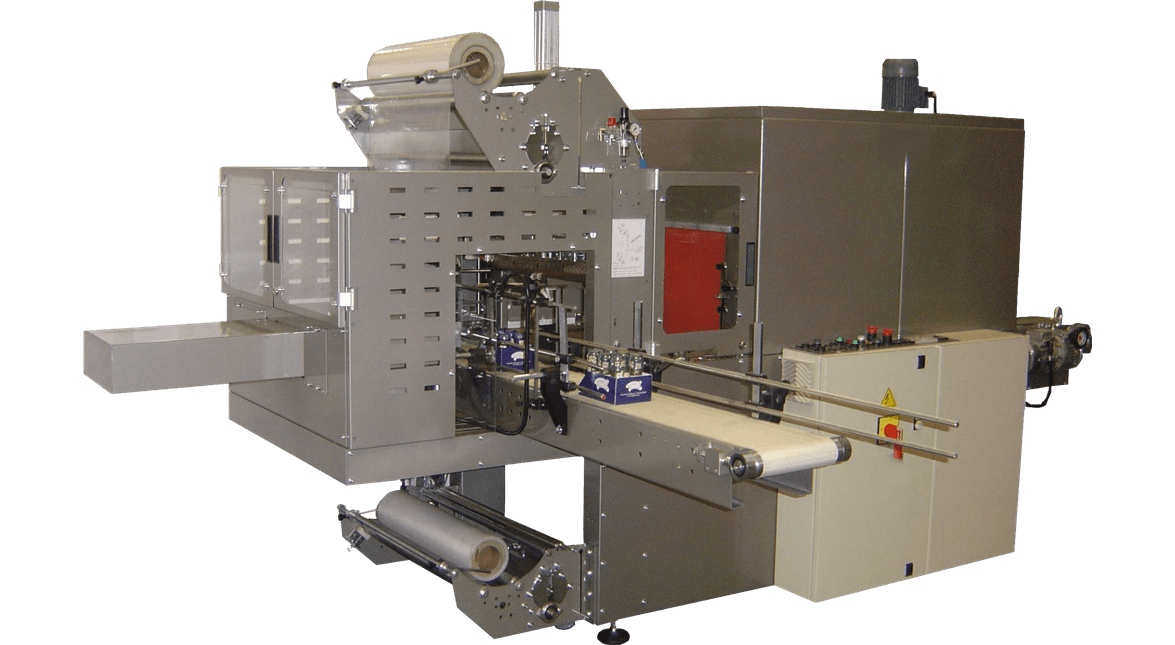

A bundling machine is a packaging machine optimized for the use of polyethylene films, suitable for packaging that requires a thicker film. Usually, bundling machines are used for the bundle packing of plastic bottles, jars of various types, cans. However, these machines are flexible enough to pack products of all kinds, both single and multiple.

All the bundling machines shown on this page are certified according to current European regulations. The wide range of options and functionality allows these sleeve wrapping machine to be particularly versatile, suitable for all packaging needs.

We build our bundling machines with an accurate study, a precise project, prototypes, tests, passion and dedication. The ideas are born in the minipackLAB, take shape in the minipackSTEEL, perfect with Quality Control as long as they are ready to fly and reach customers all over the world.

Very recent, then, is the merger of minipack®-torre with the brand Giemme, specialized for more than 20 years in the production of automatic and non-automatic shrink wrappers.

The range of minipack®-torre bundling machines is very varied and rich, with more than 50 different models. 7 are the main lines, each suitable for a particular application;

Our high-quality bundle packing machines are differentiated in:

A bundling machine of the first type is equipped with a pneumatic pusher, and can also be used in manual mode, just pressing the special switch.

An automatic bundling machine, on the other hand, works by means of a motorized tape and is ready for direct integration in the production line, thanks to the fully automatic management of the input and output exchange signals.

Shrink bundling is a packaging method that involves using heat-shrinkable film to wrap and protect single or multiple products.

This method offers several advantages, including: